HDPE 4710 POLY PIPE

Polyethylene pipe is connected through heat fusion, a technique that partially melts the pipe to then be joined to another section or fitting. The ends of the pipes to be joined are trimmed flush then placed against a heater plate. Once the ends begin to melt, the heater plate is removed, and the ends are brought together. Once cooled, the new formed joint is stronger than the pipe itself and creates a leak-free connection that is self-restrained. HDPE can be installed in several ways including above ground, direct burial, slip lining, pipe-bursting, and directional-drilling as well as be used in open-cut trenchless applications.

WHY CHOOSE HDPE?

- Economical

- Zero Leak Rate

- Hydraulically Smooth

- Long Design Life

- Easy to Install

- Corrosion Resistant

- Abrasion Resistant

- Freeze Resistant

- Impact Resistant

- Surge Resistant

- Inert

- Lightweight

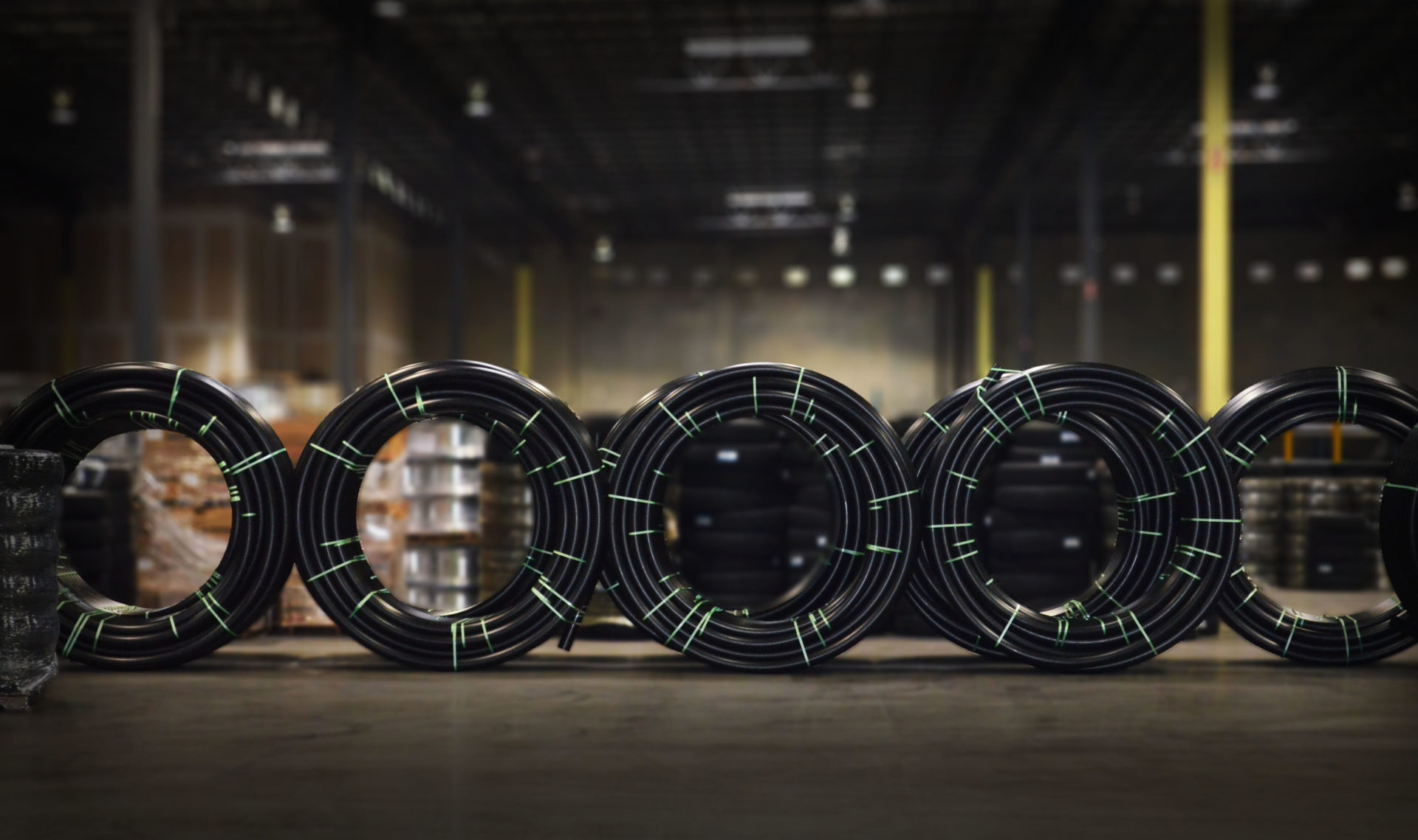

- Flexible/ Coil-able

- 100-year service life

- Listed and Approved

STANDARDS

Pipe Manufacturing Standards

- ASTM D3035

- ASTM F714

- ASTM F2619

- NSF/ANSI 14

- FM 1613

Pipe Resin Standards

- ASTM D3350

Water Works Standards

- AWWA C901

- AWWA C906

- NSF/ ANSI 61

FEATURES

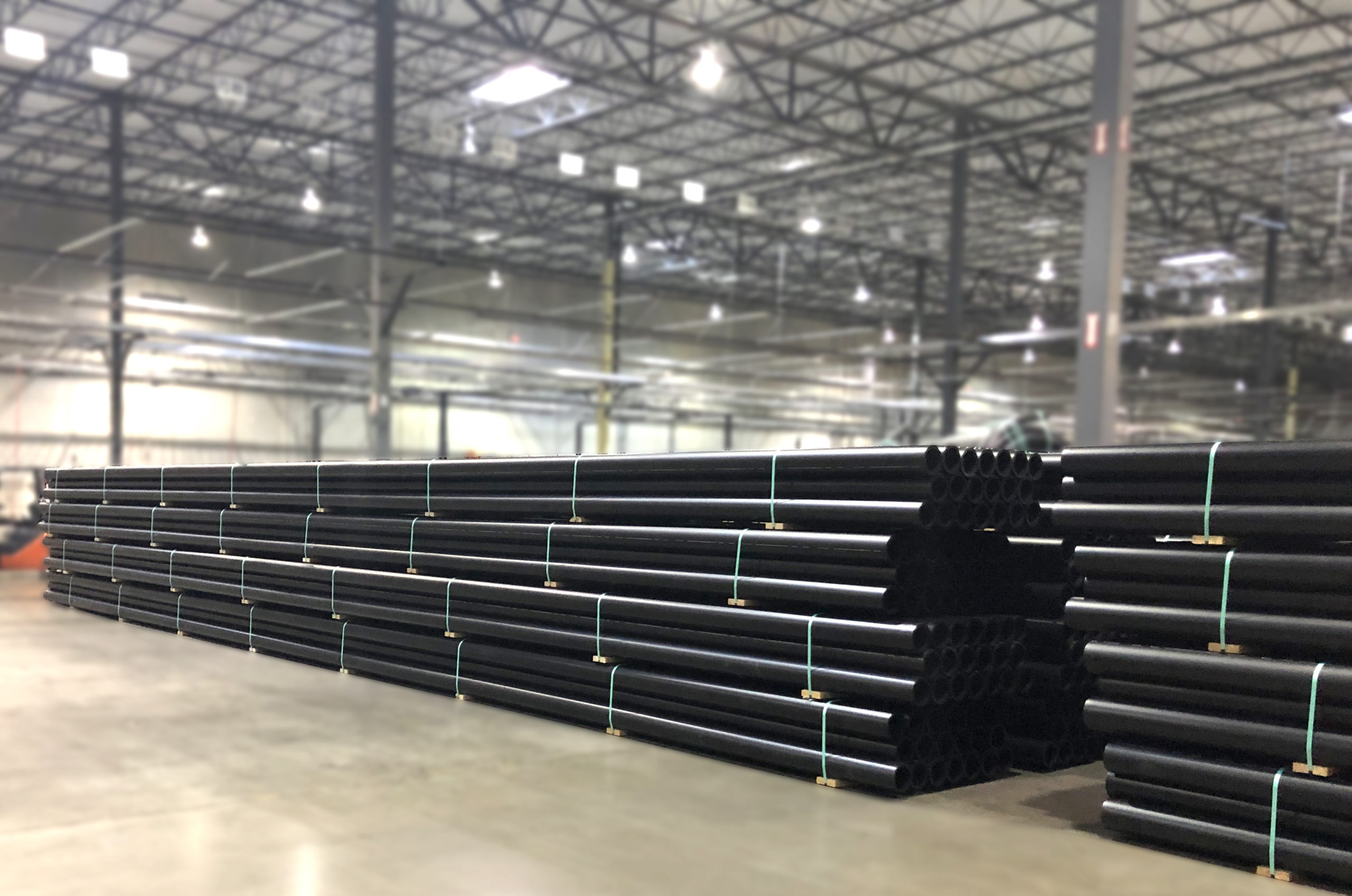

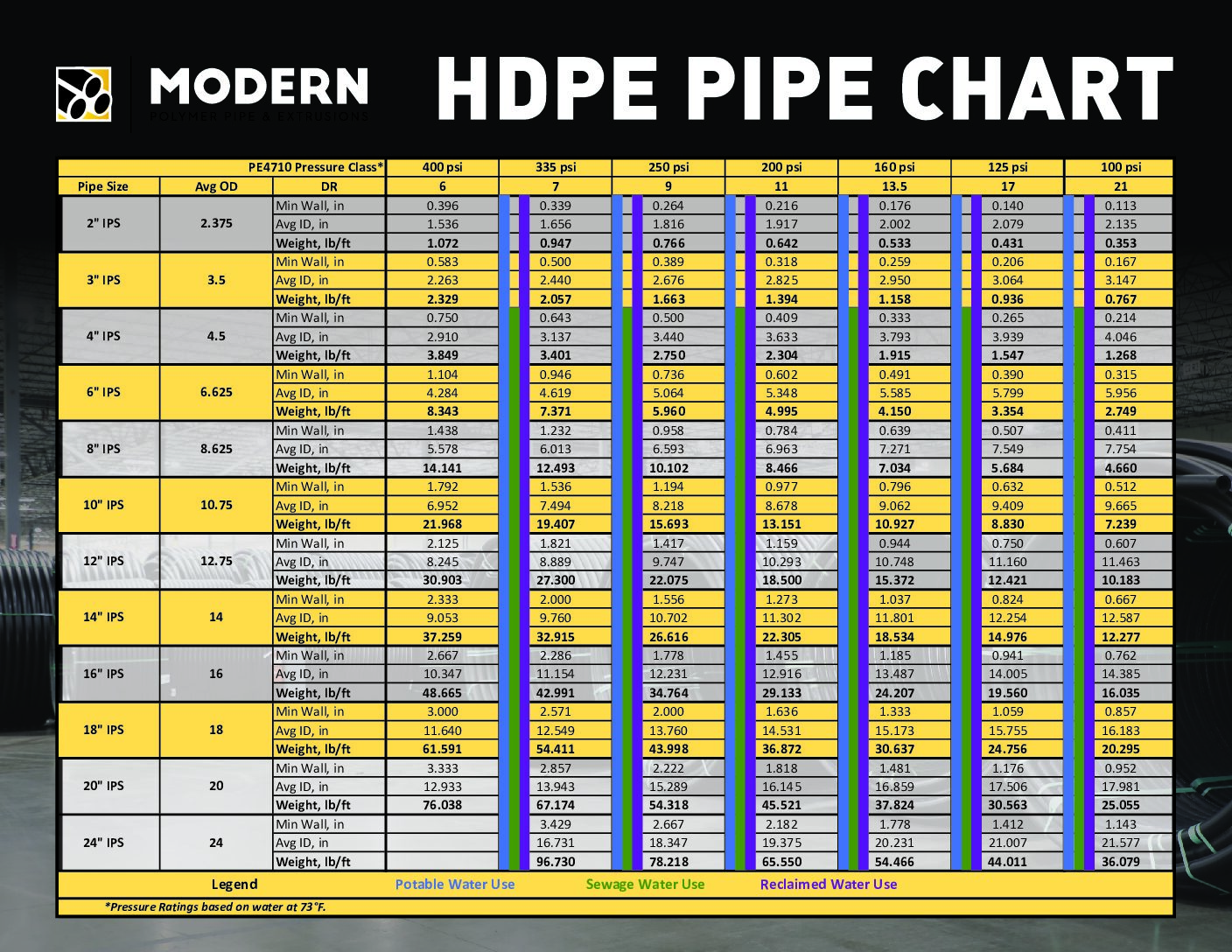

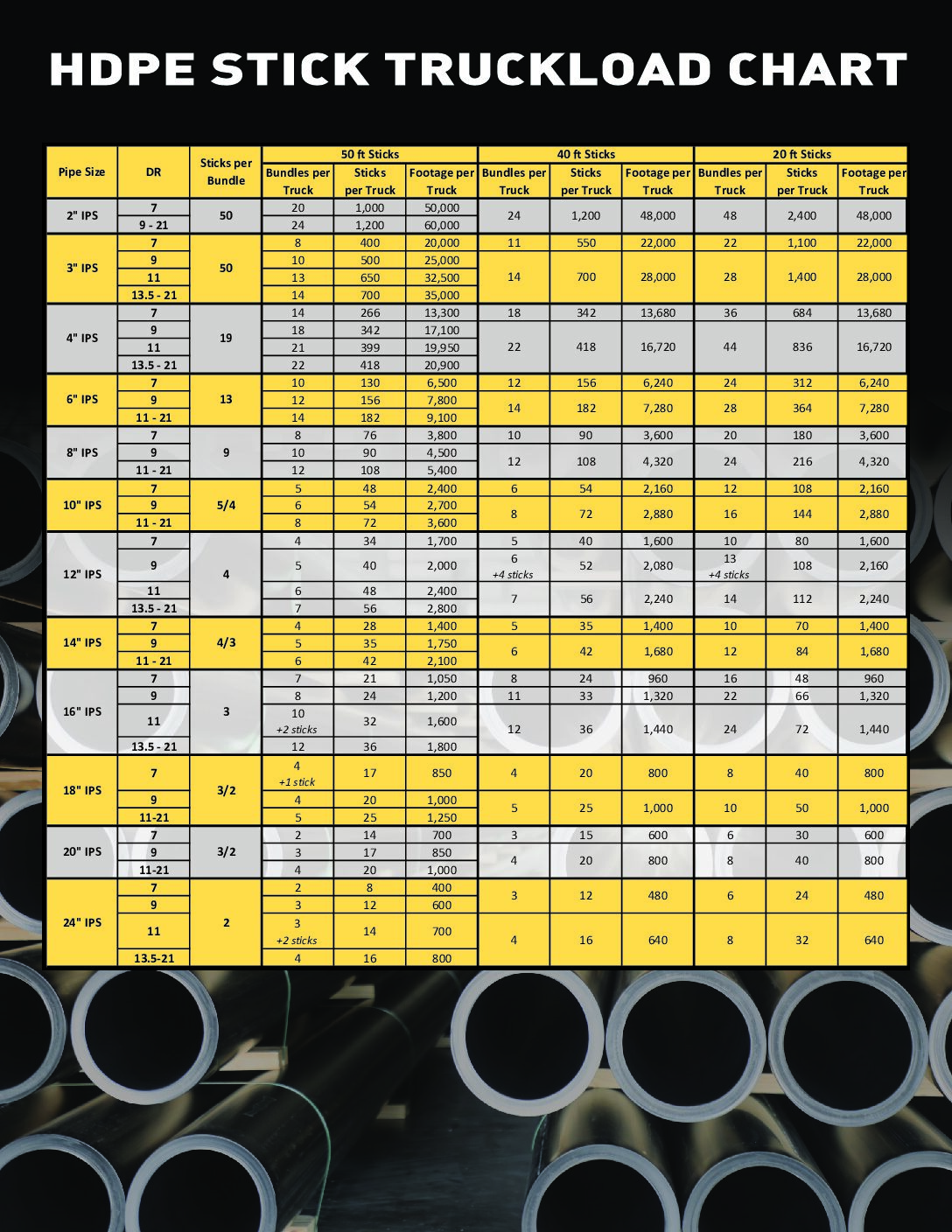

Available in sizes from 2” – 24” IPS with DR 7 – 21

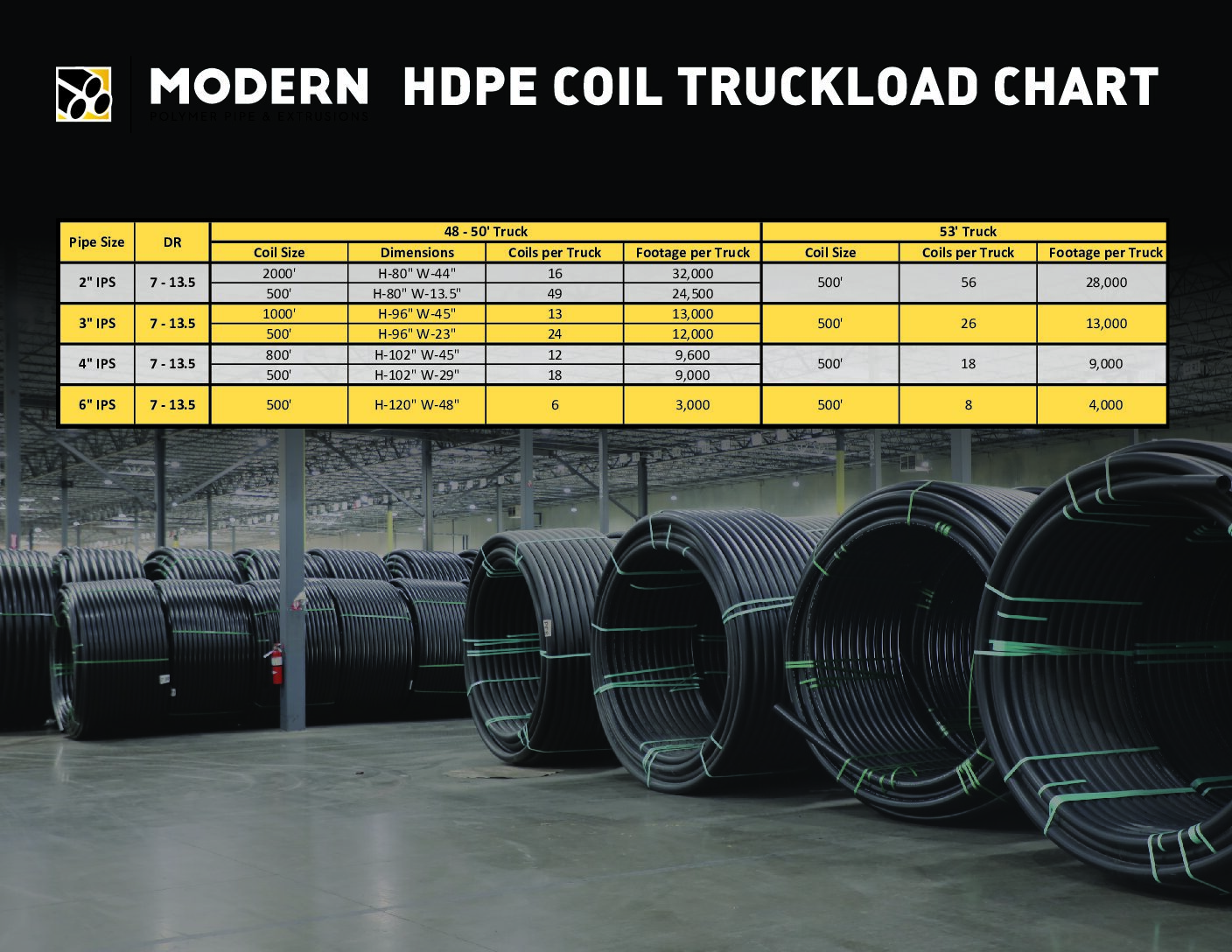

- 2” – 6”, 500/1000/2000 ft coils

- 2” – 24”, 20/40/50 ft sticks